PRODUCT

Product Introduction

——

Full automatic high pressure polyurea/polyurethane spraying system JHPK-BPT1

Product

description

- 产品描述

-

- Commodity name: Full automatic high pressure polyurea/polyurethane spraying system JHPK-BPT1

- Commodity ID: JHPK-BPT1

JHPK-BPT1 full automatic spraying system can be applied in spraying the two-components polyurea,polyurethane resin,resin,elastomer and etc..

Full automatic high pressure polyurea/polyurethane spraying system

Full automatic high pressure polyurea/polyurethane spraying system JHPK-BPT1

Product Introduction

JHPK-BPT1 full automatic spraying system can be applied in spraying the two-components polyurea,polyurethane resin,resin,elastomer and etc..

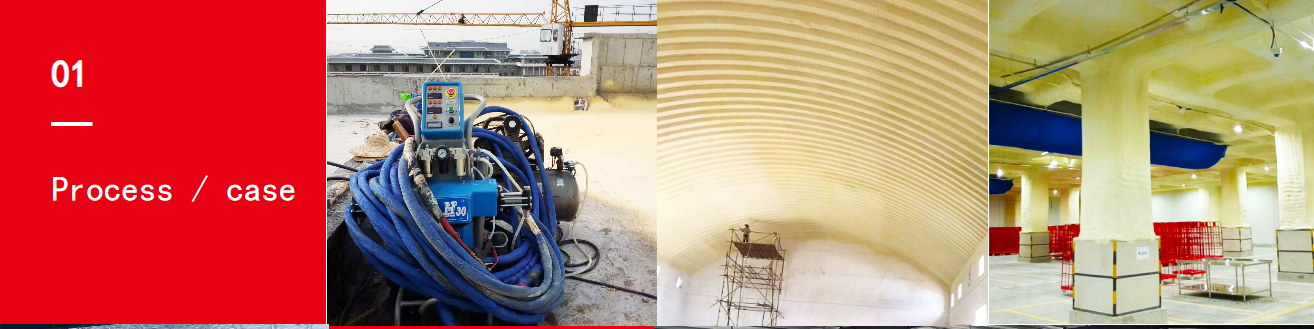

The product is widely used in various fields such as lining of the military truck,container truck,dumper,pickup truck chassis,abrasion resistance plate,military helmet,petrol chemical,anti-corrosion for piping ,tank,vibration screen,spiral separating screen,ocean buoy,marine fender,tap water,anti-corrosion for drainage piping and etc;

JHPK-BPT1 full automatic spraying system can be applied in spraying the two-components polyurea,polyurethane resin,resin,elastomer and etc..

The product is widely used in various fields such as lining of the military truck,container truck,dumper,pickup truck chassis,abrasion resistance plate,military helmet,petrol chemical,anti-corrosion for piping ,tank,vibration screen,spiral separating screen,ocean buoy,marine fender,tap water,anti-corrosion for drainage piping and etc;

JHPK-BPT1 full automatic high pressure spraying system is newly motivated.The polyurethane resin product is the best replacement for glass fiber which has very strong intensity and elasticity and has higher insulation effect for sound and heat than average level.

At present all shower bottom basin and bathtub technology in domenstic market is thermoforming with acrylic plate,then consoildated and maually or mechanically with resin and glass fiber.And bathtub sprayed with BPT1 polyurethane can be directly sprayed after the acrylic plate thermoforming .

1.Spray and stop at any time,the spraying can be stopped at any time during the operation and enables the optimization of material application;

2.Superior capability of insulation of heat and sound

3.Direct shower support(no need the wood insert)

Standard Configuration:

Main frame: 1set Feeding pump: 2 sets(JHPK-3G76) Ancillary injection gun: 1 piece Insulated pipe: 1 set 3m Connecting pipe for the gun: 1 set Ancillary piping and joints : 1 set Spare parts: 1 set Tools : 1 set English manual: 1 set Package: plywood tray Shipping Parameter:

Dimension: 1400*1230*2150mm Weight: 700Kg Technical Parameter

Raw material matching: 1:1 ~5:1 Viscosity range of raw material 200~1000CPS Outlet quantity of raw material 3~12L/min Air pressure 0.5~0.8Mpa(70~120psi)≥0.63/min Power source Three phase five wires 380V 50Hz Heating range 25℃~88℃(77°F-190°F) Heating power 2000W*2 Length of insulated pipe 8M(standard) Pressure of system raw material ≤21Mpa(3300psi) Function of spray gun Pneumatic, auto back flow Pressure of air inlet of spray gun &0.5~0.8Mpa(70~120psi) Air pipe size Ф8*1 Operation flow rate of spray gun 0~12L/min Cleaning method for spray gun Mechanical cleaning external nozzle auto cleaning device

Process / case

Process / case

Company Profile

Company ProfileJHPK company's main products are polyurethane spraying machine, polyurea spraying machine, polyurethane foaming machine, polyurethane pouring equipment, polyurethane spraying equipment, polyurethane foaming material, polyurethane black and white material, polyurethane resin pultrusion equipment, epoxy resin pultrusion equipment, unsaturated Resin pultrusion equipment, broken bridge aluminum doors and windows filling equipment, polyurethane packaging equipment, feed pump, polyurethane spray gun, polyurethane insulation pipeline, polyurethane road maintenance and lifting equipment, automatic spraying equipment, laboratory polyurethane equipment, tube-in-tube foaming equipment, intelligent two-component spraying equipment, etc.

FAQ

FAQAre you a factory? How large is the area? headquartered in Beijing, the production center moved to Weinan New District in Hebei in 2018; the production center covers an area of 63,000 square meters, about 100 acres. Is your equipment imported? The mechanical equipment produced by Jinghua Parker is composed of spare parts processed by the processing center imported from the United States, zero-matched by the domestic brand processing center, and Siemens, Schneider and other internationally renowned brand accessories. It is a pure domestic equipment and a national brand. Overseas sales are an important channel for sales of Jinghua Parker products, so the appearance of the equipment is relatively good-looking and is in line with the world. Equipment? Is it installed at home? Free delivery, free on-site installation and commissioning training services for customers in China; free export packaging services for export equipment Why is the product of Jinghua Parker recognized by the market/word of mouth? Because Jinghua Parker starts from the procurement of high-quality raw、 materials, independent processing of spare parts, strict implementation of quality inspection system, traceable finishing process, perfect product display and after-sales service of online and offline process communication, the customer is the core only to build A good mechanical device. Are your parameters accurate? Jinghua Pike's flag is against the improper behavior of some friends to exaggerate the parameters of the virtual standard equipment! Jinghua Parker rejects the virtual standard, and the parameter data of the products sold are all measured real data. I am using it abroad, can the voltage be changed? Yes, Jinghua Parker equipment is sold at home and abroad, covering more than 70 countries on five continents. How long is the warranty? One year, our service policy is comprehensive quality assurance, lifelong service  Contact information

Contact information<Mobile: 0086-13801200210 <Phone: 400-888-9616 <After-sales service: 031-05079803 <Postcode: 102609 <Mail Box: equipment@jhpk.net < <ProductionCenter: China Electronic Science and Technology Park, Hunnan New District, Hebei Province

Auxiliary Equipment

Auxiliary Equipment

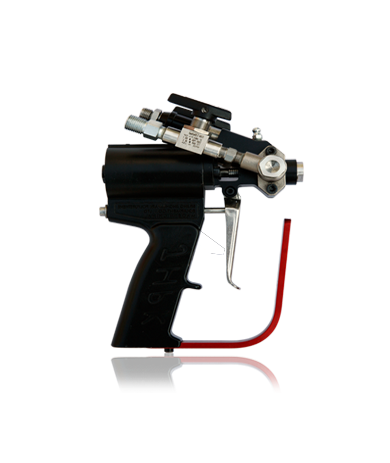

Spray/injection gun

JHPK-PK1/2/3/4

High pressure insulation pipe set

BPT1-15M

Pneumatic extraction pump / bucket pump

JHPK-3G63 Auxiliary Equipment

Auxiliary Equipment

Two-component electric spraying equipment

JHPK-DD3

Hydraulic high pressure polyurea spraying equipment

JHPK-H3500

Pneumatic high pressure polyurea/polyurethane spraying equipment

JHPK-PK1/2/3/4

Automatic polyurethane polyurea spray system

JHPK-BPT1 Auxiliary Raw Material

Auxiliary Raw Material

Full water foaming agent polyurethane raw material

JHPK-WB

Easy security door and window insulation sound insulation foam

JHPK-EANOR

Spraying series of polyurethane raw materials

JHPK-SF

Infusion series of polyurethane raw materials

JHPK-IF Related download

Related downloadPneumatic high pressure polyurea/polyurethane spraying equipment JHPK-A9000 User Manual.PDF

DownloadPneumatic high pressure polyurea / polyurethane spraying equipment JHPK-DD3 publicity coloring page.JPG

Download