PRODUCT

Product Introduction

——

零售价

市场价

重量

kg

库存

隐藏域元素占位

polyurethane resin pultrusion and winding equipment JHPK-G20A

Product

description

- 产品描述

-

- Commodity name: polyurethane resin pultrusion and winding equipment JHPK-G20A

- Commodity ID: JHPK-G20A

200~1000cps(操作温度下)2~9公斤/分钟系统原料压力: 主机原料加热功率:3000W×2(或4500W×2)管路保温加热功率:3200W加热温度范围:25℃~55℃(推荐使用)电源要求: 三项五线380V50HZ 2安培×3(含高低温循环机)气源要求:0.5~0.8Mpa(70~120psi)≥0.8m3/min灌注枪功能:气动,手柄控制开关,停枪自动回流灌注枪混合方式: 初始对撞+静态混合器灌注枪空气入口压力:0.5~0.8Mpa(70~120psi)立即购买 类似设备 配套原料 01— 施工工艺 02— 案例图片 05— 包装 06— 展会图片 1:1 FAQ 手机拨打:1390139177313801200210电话热线:010-60273028/010-60270605010-60270605/售后热线:010-60270958地址:北京市大兴区北臧建材工业区邮编:102609 系统流量: 03— 生产 04— 质检 全水发泡剂聚氨酯原材料EANOR易安能门窗保温隔音泡沫JHPK喷涂系列聚氨酯原料JHPK灌注系列聚氨酯原料 出口型高压聚氨酯喷涂/灌注设备 全自动聚氨酯聚脲喷涂系统配套设备 出口型高压聚氨酯喷涂/灌注设备 气清洁聚氨酯喷涂、灌注枪 04— 质检 05— 包装 气清洁聚氨酯喷涂、灌注枪 北京京华派克聚合机械设备有限公司成立于2003年,拥有几十项研发专利,是一家国家级高新技术企业相关下载 下载北京京华派克聚合机械设备有限公司成立于2003年,拥有几十项研发专利,是一家国家级高新技术企业 下载 一台好用的喷涂设备的标准都在A9000上得到体现 产品简介联系方式 标准配置系统主机: 配套喷枪: 加热保温管路1组:1台1把 8m或选配连枪短管1组:3米配套灌注枪:1把枪用操作台车:1个配套辅助管路接头:1套 技术参数 系统比例 : 原料粘度:≤2.9Mpa(400psi) 加强型聚氨酯气动喷涂/灌注设备立即购买 工艺/案例 京华派克公司成立于2003年,拥有几十项研发专利,是一家高新技术企业,北京市专利试点单位。公司总部位于北京,生产基地位于河北省邯郸市冀南新区,占地100亩,于2017年正式投入使用,致力于打造中国最大的流体设备制造中心。 公司是集研发、生产、制造、销售聚氨酯高压无气喷涂(灌注)设备、双组份聚脲高温高压喷涂设备、聚氨酯树脂拉挤注胶设备、双组份聚氨酯淋胶设备、自动化喷涂设备等各种设备的集合性企业。 北京京华派克聚合机械设备有限公司成立于2003年,拥有几十项研发专利,是一家国家级高新技术企业,北京市专利试点单位。公司总部位于北京,生产基地位于河北省邯郸市冀南新区,占地100亩,于2017年正式投入使用,致力于打造中国最大的流体设备制造中心。公司是集研发、生产、制造、销售聚氨酯高压无气喷涂(灌注)设备、双组份聚脲高温高压喷涂设备、聚氨酯树脂拉挤注胶设备、双组份聚氨酯淋胶设备、自动化喷涂设备等各种设备的集合性企业。本企业有严格的科学管理制度和完善的质量保证体系,在积累多年生产经验的同时,也广泛吸收了国内外先进技术。公司产品在海内外流体设备行业均享有盛名。在中国市场占有率高达66.2%,售后服务网络遍布全国。而且设备远销海外美国、加拿大、智利、秘鲁、澳大利亚、马来西亚、印度、泰国、越南、阿联酋、沙特、约旦、捷克、波兰、英国、爱尔兰等70多个国家,遍布全球。公司简介 05— 包装 03— 生产 气动提料泵/插桶泵 高压保温管组聚氨酯树脂复合材料拉挤注胶系统JHPK-G20A自主知识产权设计生产,且带有专利保护的平置泵系统,有多种规格和动能形式供客户选用。多项关键技术申报发明专利;本系统特别针对聚氨酯型材拉挤缠绕生产线设计开发;电机驱动,数字化控制,动作灵敏,精度高。无味,拉挤产品效率快速成型,结构稳定性强;特有的平置式结构,解决了传统竖置泵压力及柱塞自身速度对原料泵送的影响。换向平稳可靠,基本无压力波动,泵送原料时的压力恒定平稳。任一单位节点处原料流量均一致,可以时时保证稳定高精度的泵送比例。可实现范围内比例调节,且流量覆盖区间广,精度高。所有动密封处均涉及有磨损补偿功能,大大的提高了泵的使用寿命。选用不同的密封材料及轴筒即可满足耐腐蚀性,耐酸碱度的使用要求,还可泵送带填料的原料。动力强劲,无內泄及溢流,可持续进行高压泵送工作。带有专利保护的全泵闭环必环防固化工作系统,解决了原料亲水性产生的不利影响。高精密系统,建议使用厂家专业推荐原料,避免因原料损坏系统而造成的经济损失。设计时对不同截面及不同规格型材生产工艺的充分考虑,使系统具有高度的适用性。专业开发的系统主机确保系统连续稳定工作,使高度自动化流水线生产作业成为可能;合理的系统布局充分节省了生产空间,优化人员配置和原材料的充分利用,大限度的节约了生产成本;系统可实时监测拉挤速度,并根据速度变化自动调整原料输出量,实现生产随动超速报警。系统可智能监测原料罐内的原料量,根据设定参数自动补料,保证系统供料充足。系统化的限位功能和故障报警提示功能的设置,大限度的保证生产操作的正常进行和人员的平安;全智能数字化控制系统设计,使系统的操作控制更加直观便捷;特有的系统防原料沉淀分层功能设计,可有效应对原料沉淀分层特性对产品品质的影响。装运参数外形尺寸及重量(净) 高低温循环机:1300mm×1200mm×2100mm(长×宽×高)800mm×600mm×1070mm(长×宽×高) 气管尺寸: φ8×1灌注枪工作流量:0.5~0.8Mpa(70~120psi)灌注枪清洁方式:清洗液清洗+空气清洗按序组合(或选择单一清洗方式)配套枪用操作台车:500mm×500mm×800mm(不含枪用支撑部分)

polyurethane resin pultrusion and winding equipment

polyurethane resin pultrusion and winding equipmentJHPK-G20A

Product Introduction

The newest promoted high performance JHPK-A9000 pneumatic ultrahigh pressure spraying & injection equipment with double component system can be applied under various construction situations and suitable for multiple double component materials, such as polyurea elastomer, polyurethane all-water foam, polyurethane foam material, polyurethane adhesive and sealants.

Our company has newly promoted JHPK-G20A complementary perfusion system for profile extruding production line. The system has various types according to different flow rate. It can be applied in the new type polyurethane profile extruding production which can completely replace the fiberglass extruding profile, including the polyurethane profile of window and door, polyurethane guide groove, polyurethane pipe and other molding products.

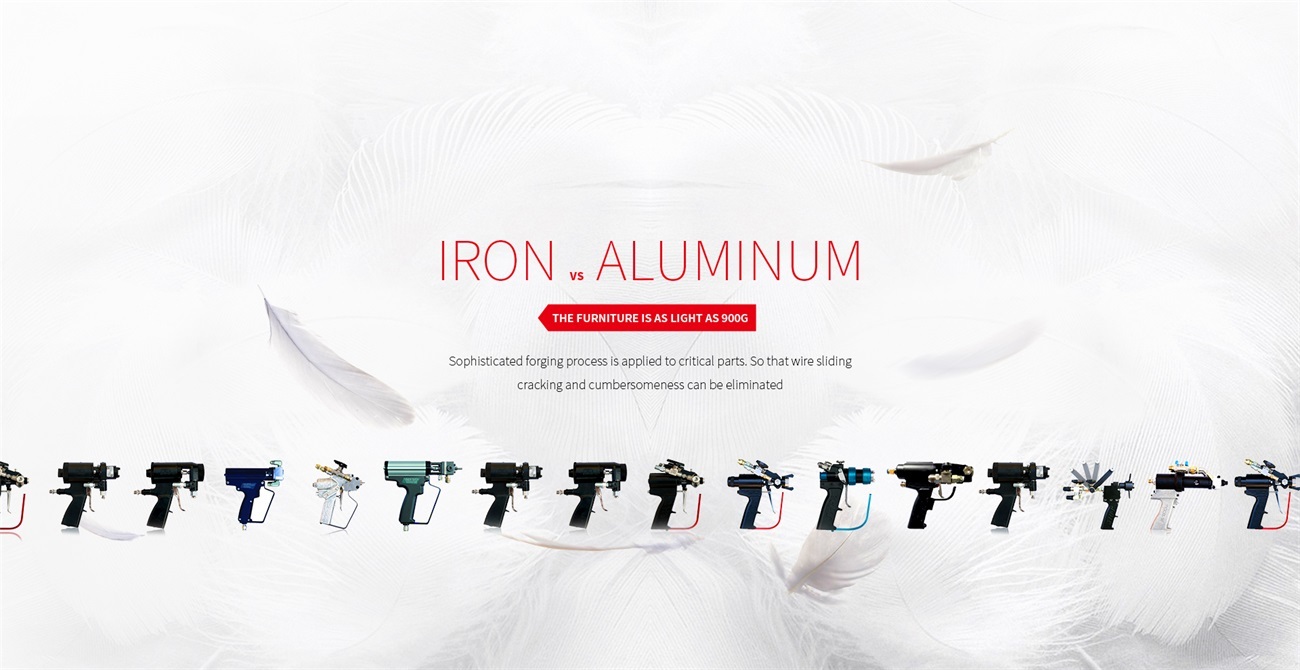

Having the complete independent intellectual property rights in design and with the patent protection horizontal pump system which has several types and forms of kinetic energy for customer’s selection, and several key techniques have applied national patents;

The system is especially designed and produced for polyurethane profile extruding and winding production line; electric driven, digital control, action sensitive, high accuracy;

Every dynamic seal has abrasion compensation function which greatly enhanced the lifetime of the pump;

The application of the different sealing material and shaft barrel can meet the demand of the corrosion resistance and acid-alkaliresistance as well as pumping filling material’ The system can realize the constant monitoring for extruding speed and automatically adjust the output quantity of the raw material according to the speed changing.Therefore the constant alarm for overspeed during the production is realized;

Standard Configuration:

Main equipment: 1 set Spray gun: 1 group Ancillary perfusion gun: 1 piece Operation panel for gun: 1 piece Insulated pipe: 1 group Auxiliary piping and joints: 1 set Shipping Parameter:

Dimension: 1300mm×1200mm×2100mm Weight: 150Kg Technical Parameter

Ratio of raw materials: 1:1 Viscosity range: 200~1000CPS Output of raw materials: 2~9L/ min Heating power: 6000W*2 Hose heating power: 3200W Heating temperature range: 0℃~90℃ Power source: 3-phase 4-wires, 380V, 50Hz, or it can be customized Air Source: 0.5-0.8Mpa(70~120psi) ≥1.2m3/min Output pressure: 9~20 Mpa(1300~2900PSI) Max. length (optional): 90 meter Gun cleaning way: mechanical cleaning and air cleaning

Process / case

Process / case

Company Profile

Company ProfileJHPK company's main products are polyurethane spraying machine, polyurea spraying machine, polyurethane foaming machine, polyurethane pouring equipment, polyurethane spraying equipment, polyurethane foaming material, polyurethane black and white material, polyurethane resin pultrusion equipment, epoxy resin pultrusion equipment, unsaturated Resin pultrusion equipment, broken bridge aluminum doors and windows filling equipment, polyurethane packaging equipment, feed pump, polyurethane spray gun, polyurethane insulation pipeline, polyurethane road maintenance and lifting equipment, automatic spraying equipment, laboratory polyurethane equipment, tube-in-tube foaming equipment, intelligent two-component spraying equipment, etc.

FAQ

FAQAre you a factory? How large is the area? headquartered in Beijing, the production center moved to Weinan New District in Hebei in 2018; the production center covers an area of 63,000 square meters, about 100 acres. Is your equipment imported? The mechanical equipment produced by Jinghua Parker is composed of spare parts processed by the processing center imported from the United States, zero-matched by the domestic brand processing center, and Siemens, Schneider and other internationally renowned brand accessories. It is a pure domestic equipment and a national brand. Overseas sales are an important channel for sales of Jinghua Parker products, so the appearance of the equipment is relatively good-looking and is in line with the world. Equipment? Is it installed at home? Free delivery, free on-site installation and commissioning training services for customers in China; free export packaging services for export equipment Why is the product of Jinghua Parker recognized by the market/word of mouth? Because Jinghua Parker starts from the procurement of high-quality raw、 materials, independent processing of spare parts, strict implementation of quality inspection system, traceable finishing process, perfect product display and after-sales service of online and offline process communication, the customer is the core only to build A good mechanical device. Are your parameters accurate? Jinghua Pike's flag is against the improper behavior of some friends to exaggerate the parameters of the virtual standard equipment! Jinghua Parker rejects the virtual standard, and the parameter data of the products sold are all measured real data. I am using it abroad, can the voltage be changed? Yes, Jinghua Parker equipment is sold at home and abroad, covering more than 70 countries on five continents. How long is the warranty? One year, our service policy is comprehensive quality assurance, lifelong service  Contact information

Contact information<Mobile: 0086-13801200210 <Phone: 400-888-9616 <After-sales service: 031-05079803 <Postcode: 102609 <Mail Box: equipment@jhpk.net < <ProductionCenter: China Electronic Science and Technology Park, Hunnan New District, Hebei Province

Auxiliary Equipment

Auxiliary Equipment

Spray/injection gun

JHPK-PK4

High pressure insulation pipe set

A9000-15M

Pneumatic extraction pump / bucket pump

JHPK-3G63 Auxiliary Equipment

Auxiliary Equipment

Two-component electric spraying equipment

JHPK-DD3

Hydraulic high pressure polyurea spraying equipment

JHPK-H3500

Pneumatic high pressure polyurea/polyurethane spraying equipment

JHPK-H30

Automatic polyurethane polyurea spray system

JHPK-IIIB Auxiliary Raw Material

Auxiliary Raw Material

Full water foaming agent polyurethane raw material

JHPK-WB

Easy security door and window insulation sound insulation foam

JHPK-EANOR

Spraying series of polyurethane raw materials

JHPK-SF

Infusion series of polyurethane raw materials

JHPK-IF Related download

Related downloadPneumatic high pressure polyurea/polyurethane spraying equipment JHPK-A9000 User Manual.PDF

DownloadPneumatic high pressure polyurea / polyurethane spraying equipment JHPK-DD3 publicity coloring page.JPG

DownloadKey words:- 聚氨酯拉挤

- 聚氨酯树脂

- 聚氨酯树脂拉挤设备