Opportunities with Injection Foam

Release time:

Opportunities with Injection Foam

By Ryan Spencer

If you’ve spent any time in the commercial side of the SPF industry, particularly working with CMU buildings, you may have heard the term ”injection foam” thrown around, albeit referencing something other than polyurethane foam. Indeed, there is another kind of foam insulation peaking the interest of not only major retailers like Wal-Mart and Publix Supermarkets, who are specifying it for their stores, but also SPF contractors, who see an avenue through which to expand their business.

”We get a lot of questions from spray foam installers,” said cfiFOAM President Richard Porter, who further mentioned that once these questions were answered, many SPF installers also become injection foam installers. The similarities between the two products are favorable for SPF contractors who are looking to provide additional service offerings, and this Editorial Spotlight on Injection Foam will discuss why.

PRODUCT

When comparing injection foam to the spray foam and pour foam that SPF contractors are familiar with, there are some similarities in the sense that both are two-component foam insulation (though not the same components). The similarities end there, however.

“It’s a different kind of foam that was designed for injection into existing cavities,” said Porter. “Categorically, it’s called aminoplast.”

Like spray foam, aminoplast foam is a two-component product wherein a resin is mixed with a catalyst to produce foam. For years, the resin component was a premixed liquid, but more recently, a dry, concentrated resin formulation has become the industry standard, as it has inherently lower VOC content, is less expensive to distribute, and has a longer shelf life. In terms of appearance, aminoplast foam is white, as opposed to the yellowish hue of SPF, and has a texture more similar to soft open-cell foam than rigid closed-cell foam.

“In terms of physical properties, our injection foam is about 60% closed-cell, and about 40% open-cell,” said Porter. “It doesn’t have vapor barrier properties or offer structural support, but in terms of R-value, it’s R-4.5 per inch.”

Specifically, aminoplast foam is a more forgiving material to install than polyurethane foam, primarily because it’s installed as pre-expanded foam, as opposed to a liquid. Because it only flows through cavities, rather than expands as it flows like SPF, aminoplast foam minimizes the risk of blowing out plaster or cracking drywall.

PROCESS

Concerning the application process, the major takeaway is that aminoplast foam is not polyurethane foam, so it cannot be installed with SPF equipment. Although it requires special equipment, the application of aminoplast injection foam is such that it presents a minor learning curve for seasoned SPF contractors.

“A lot of our current customers are already in the spray polyurethane foam business,” said Porter. “Spray foam installers really understand a lot about two-component foams, so training lasts a day or two.”

Injection foam training can be done at a facility or in the field. Training involves: explaining the basics of the materials and equipment; going through the safety protocol of working with the chemicals; operating the equipment; mixing the components to make some foam; teaching about quality control aspects; and, finally, injecting foam insulation. Once on the job site, particularly for commercial projects, the installation process is fairly methodical.

“Typically, you’re drilling holes about five feet off the ground, every eight inches or wherever there’s a core,” explained Porter. “Then you pump the foam in, drilling periodic test holes at the top of the walls to make sure the foam is flowing all the way up to the roof line.”

It should be noted that prep work and cleanup aren’t labor-intensive, in terms of masking and protective sheeting, because injection foam doesn’t adhere to substrates like SPF particulates do. It’s also worth mentioning that safety considerations for injection foam are considerably less involved than those of SPF, as there are fewer health risks associated with aminoplast foam. Specifically, protective suits and fresh air masks aren’t required for installers or other trades, although gloves and protective eyewear are recommended.

Because the injection foam process is a bit simpler than spraying foam, installers who are adept at that process will take to injection foam quite easily. Furthermore, when contrasting SPF installers’ body of knowledge with that of contractors who install other insulation materials, Porter explained that, “guys who have installed fiberglass batt insulation all their careers won’t do particularly well with injection foam or spray foam without quite a bit of training–there’s a technology threshold, if you will.” That technology threshold not only makes injection foam a relatively easy jump, but also a fairly secure one, in terms of potential outside competition.

MARKET

Generally speaking, the injection foam market is occupied by two sets of installers: those who insulate commercial masonry buildings and those who retrofit existing homes or offices (there is also a niche market for filling in decommissioned underground storage tanks).

“In the retrofit market, there is enormous growth opportunity, and there always will be,” explained Porter. “There are supposedly 85 million houses in the U.S. that don’t have any insulation at all–virtually an untapped market.”

For the commercial side of the market, the opportunity is cloudy, but promising, due to recent developments.

“Commercial block could be a shrinking market but for one thing: the concrete masonry industry has worked with ASTM to change the standard by which concrete blocks are made,” Porter explained. “The change has brought new life to an industry that was mature and in the harvest mode of its lifecycle.”

Basically, advancements in concrete block design have entailed increasing the proportion of the cores, or hollow cavities, to the overall size of the block, as well as reducing the thickness of the webs, which are the solid parts on the inside of the blocks.

“That means there is less heat transfer that occurs through the walls,” explained Porter. “So, the R-values are quite a bit higher now–high enough to keep up with new, ever-changing energy codes.”

CONTACT cfiFOAM:

Direct any questions about injection foam products, equipment, or training to cfiFOAM:

Phone: 1-800-656-3626

Website: www.cfifoam.com

Refer to : http://sprayfoammagazine.com/opportunities-with-injection-foam/

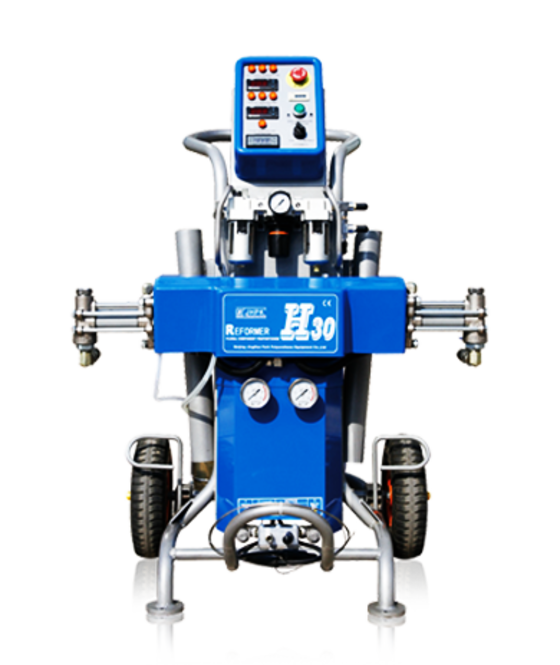

You may like JHPK PU polyurethane injection foam machine, they can operate easily and less weight and smart one, check the following images, if you are interested in them, kindly contact us directly.

previous page

previous page

previous page